All Multiple Size And low price stainless steel High Quality U Bolts With Factory Direct Sales

A U-bolt is a type of fastener shaped like the letter "U," designed to secure objects to a surface or support structure. Typically made from high-strength steel, U-bolts are commonly used in automotive, construction, and plumbing applications to secure pipes, rods, or cables. They feature threaded ends that accommodate nuts for tightening. U-bolts come in various sizes and coatings to resist corrosion and enhance durability. Their design allows for easy installation and provides a robust hold, making them ideal for both heavy-duty and light-duty applications.

structural design

The U-bolt is a type of fastener shaped like the letter "U," commonly used to secure pipes or other cylindrical objects. Its structure consists of a curved section with two straight arms extending downward, which are often threaded to accommodate nuts for fastening. When designing a U-bolt, several factors must be considered, including the material selection, load-bearing capacity, and corrosion resistance. The diameter of the U-bolt should match the size of the pipe or object it secures, while the length of the arms must allow for proper adjustment and secure fastening. Additionally, the thickness of the steel should be sufficient to withstand tension and shear forces without deformation.

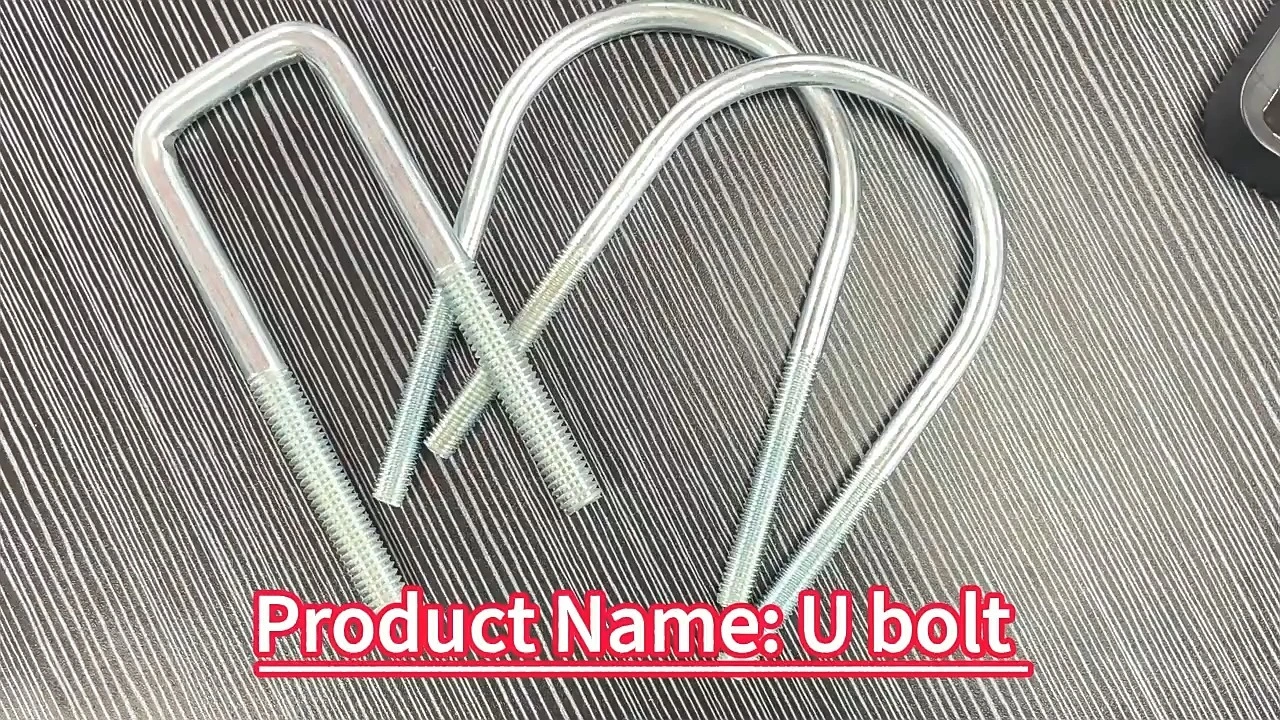

Product Display

application scenario

U-bolts are commonly used in various applications due to their unique shape and versatility. They are primarily utilized in securing pipes, tubes, and other cylindrical objects to a surface or framework. In the construction industry, U-bolts play a crucial role in anchoring structures, supporting beams, and stabilizing equipment. They are often employed in automotive applications to secure exhaust systems, leaf springs, and frames. Additionally, U-bolts are widely used in the agricultural sector for fastening components of machinery and trailers. Their ability to provide strong clamping force and resistance to shear makes them ideal for both indoor and outdoor environments. Overall, U-bolts are essential components in various industrial, commercial, and residential projects, ensuring stability and safety in construction and machinery applications.

Maintenance and repair

U-bolts require regular maintenance to ensure their longevity and effectiveness. Inspect U-bolts for signs of wear, corrosion, or damage, especially in harsh environments. Clean them periodically to remove dirt and debris, which can lead to rust. Ensure that they are properly torqued to the manufacturer’s specifications, as loose bolts can compromise structural integrity. If any U-bolt shows significant wear, replace it immediately. Additionally, consider applying a protective coating or lubricant to prevent corrosion and enhance performance. Regular checks and prompt attention to any issues will help maintain their reliability in various applications.