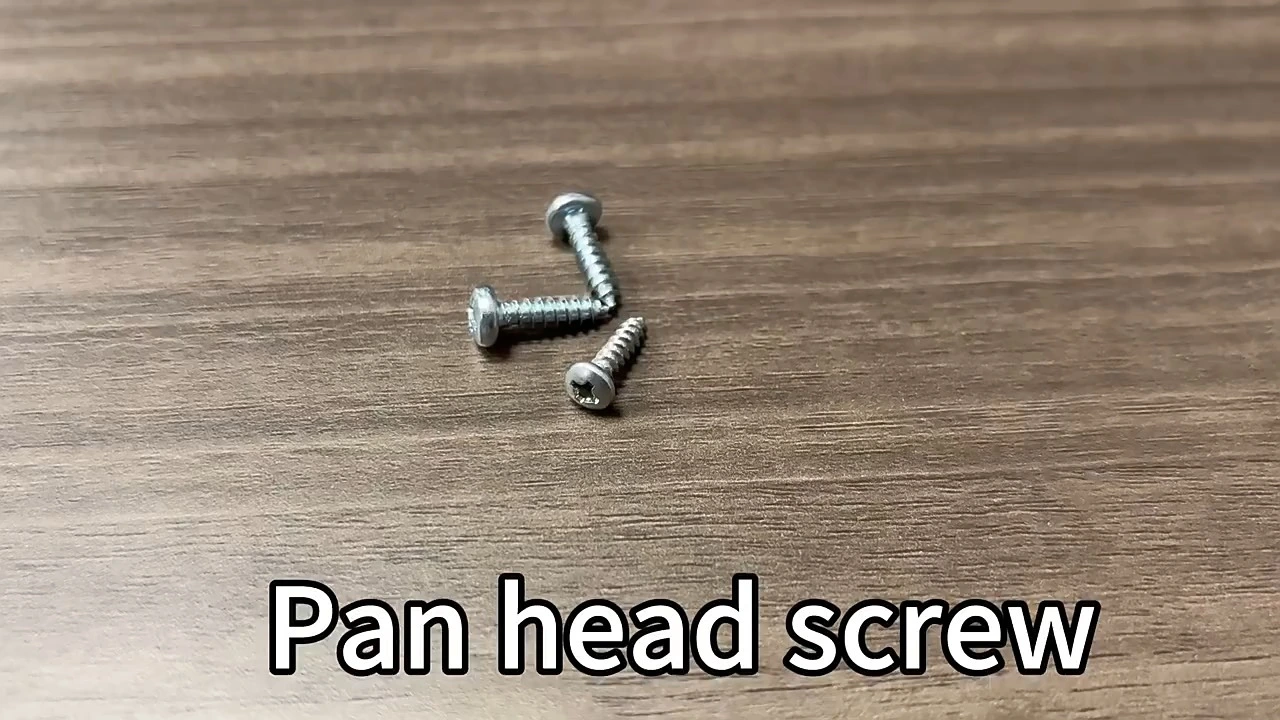

Factory Direct 304 JISB1122T Cross Recessed Truss Head Tapping Screws Stainless Steel Metal Drilling Screw

Self-tapping screws are specialized fasteners designed to create their own mating thread when driven into materials, typically metal or plastic. These screws feature a sharp point and spiral threads that enable them to penetrate surfaces without the need for pre-drilled holes. Their design allows for quick and efficient assembly, making them ideal for various applications, including construction, automotive, and electronics. Self-tapping screws come in various sizes, materials, and finishes to suit different environments and requirements. Common materials include stainless steel, carbon steel, and plastic, which provide varying degrees of strength and corrosion resistance. Due to their ease of use and versatility, self-tapping screws are widely used in DIY projects and industrial applications alike. They provide a reliable fastening solution that can improve efficiency and reduce assembly time, making them a preferred choice for engineers and manufacturers.

Product Display

Advantages of Self-tapping screws

application scenario

Woodworking: Self-tapping screws are often used in furniture assembly and carpentry, as they can easily penetrate wood and provide strong joints.

Metal Fabrication: They are used in metal-to-metal applications where pre-drilling is not feasible, allowing for quick assembly of metal components.

Construction: In construction, self-tapping screws are used for securing drywall, roofing materials, and other building elements.

Automotive: These screws are commonly found in automotive applications, securing various parts and components within vehicles.

Electronics: Self-tapping screws are used in the assembly of electronic devices, securing circuit boards and other internal components.

HVAC Systems: They are used to assemble components of heating, ventilation, and air conditioning systems.

Home Improvement: Self-tapping screws are popular in DIY projects and home repairs for their ease of use and versatility.

Material Introduction

Self-tapping screws are typically made from various materials, depending on their intended application. Common materials include carbon steel, stainless steel, and various alloys.

Carbon steel is often used for general-purpose self-tapping screws due to its strength and affordability. However, it may be prone to rust and corrosion if not coated or treated properly. Stainless steel is preferred for applications requiring corrosion resistance, such as in outdoor or marine environments. It provides durability and longevity but can be more expensive.

Some self-tapping screws are made from brass or zinc-plated steel, which enhances corrosion resistance while maintaining a lightweight profile. Additionally, specialized coatings like black oxide or epoxy can provide further protection against wear and environmental factors. The choice of material plays a crucial role in the screw's performance, affecting factors such as tensile strength, corrosion resistance, and overall durability. Proper selection ensures optimal functionality for specific applications, making self-tapping screws versatile and widely used in various industries.