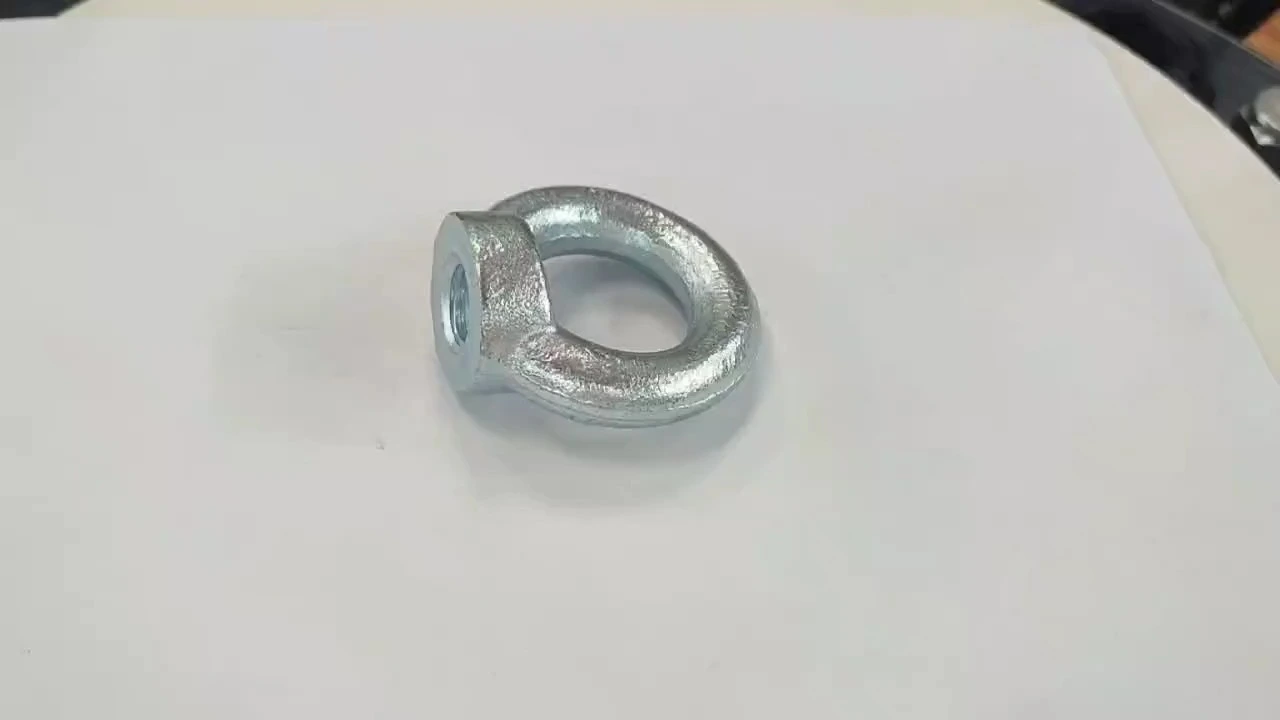

Industrial Use Stainless Steel DIN Standard Lifting eye nuts Available All Multiple Size Direct Factory Sale

The lifting eye nut is a crucial hardware component designed for secure lifting and rigging applications. Typically made from robust materials like steel or stainless steel, it features a threaded design for easy attachment to various equipment. Ideal for industrial and construction settings, it ensures safe and efficient load handling.

structural design

A lifting eye nut is a specialized fastener designed for lifting applications. It typically features a round, threaded body with an integral eye loop at the top, allowing for easy attachment of lifting cables or hooks. The eye is usually large enough to accommodate various lifting devices, ensuring versatility. Made from durable materials such as steel or alloy, the lifting eye nut is engineered to withstand significant loads and stresses. Its threaded design allows for secure anchoring into structures, providing stability during lifting operations. The combination of strength and functionality makes it essential in construction and industrial lifting tasks.

Product Display

Strong, Reliable, Essential

Firstly, their design provides a secure attachment point for lifting loads, enhancing safety during operations. They are made from durable materials, ensuring high strength and resistance to wear and corrosion. This durability makes them suitable for various environments, including construction and industrial settings. Additionally, lifting eye nuts are easy to install and can be quickly connected or disconnected, saving time during setups. Their versatility allows for use with different lifting equipment, making them an essential component in material handling and logistics.

Material Introduction

A lifting eye nut is a specialized fastener designed for lifting applications, typically made from durable materials such as steel, stainless steel, or alloy. Steel eye nuts are known for their strength and are often coated to resist corrosion. Stainless steel variants offer enhanced corrosion resistance, making them suitable for marine or outdoor environments. Proper material selection is crucial to ensure the eye nut can withstand the intended load and environmental conditions.