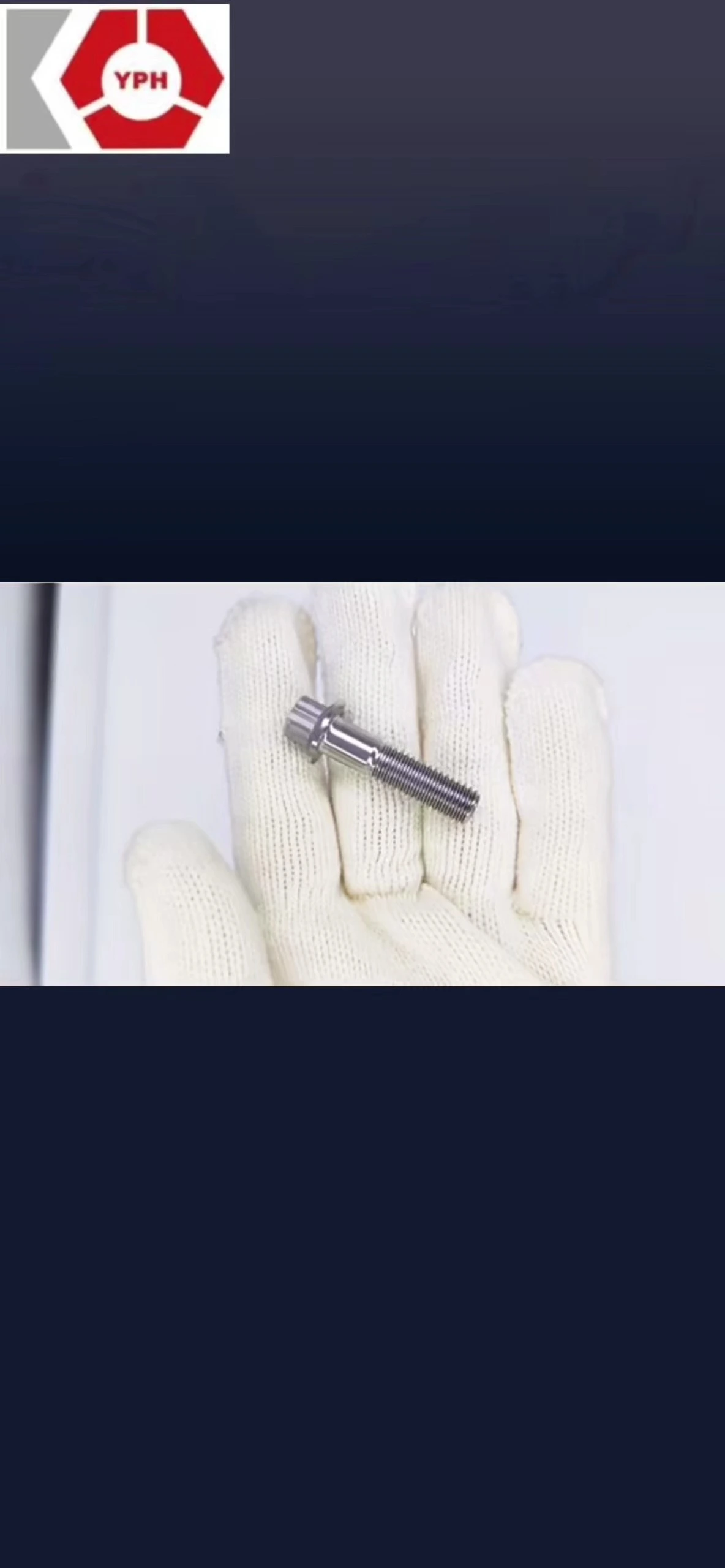

High Quality M5 Titanium 12-Point Flange Bolt Automotive Flanged Bolts Steel DIN Various Sizes Plain

Flange bolts are specialized fasteners characterized by a flange at one end, which provides a larger surface area for load distribution and prevents the bolt from pulling through the materials being joined. They are commonly used in applications that require a secure and stable connection, such as in piping systems, machinery assembly, and structural engineering. Flanged bolts can be made from various materials, including stainless steel and carbon steel, and are available in different sizes and grades to meet specific strength and corrosion resistance requirements. Their design enhances assembly efficiency and durability in critical applications.

structural design

A flange bolt, commonly used in piping and structural applications, features a head that is wider than the shank, providing a larger bearing surface. The design includes a smooth shaft to reduce friction and facilitate easy installation. Flange bolts come with different head styles, such as hex or square, allowing for compatibility with various tools. The flange itself helps distribute the load over a larger area, reducing the risk of damage to the connected materials. These bolts are typically made from high-strength materials to ensure durability and reliability in demanding environments.

Product Display

Types and specifications

Flange bolts, commonly used in piping and mechanical assemblies, come in various types and specifications. The most common types include hex flange bolts, which have a built-in washer, and serrated flange bolts, designed to prevent loosening due to vibration. Specifications often refer to diameter, length, and grade, such as ASTM A325 or A490 for structural applications. Standard sizes typically range from 1/4 inch to 1 inch in diameter, with lengths varying from 1 inch to several feet. It's essential to select the appropriate type and specification based on the specific application requirements.

Material Introduction

Flange bolts are typically made of high-strength alloy steel or stainless steel to ensure their reliability and corrosion resistance under high pressure and high temperature conditions. Common materials include 8.8 and 10.9 grade high-strength steel and 304 and 316 stainless steel. The surface treatment of flange bolts often uses galvanizing or heat treatment to enhance their oxidation resistance and mechanical strength. According to specific application requirements, selecting appropriate materials and surface treatment methods can effectively improve the safety and service life of connectors.